Rumored Buzz on 24hr Media

Rumored Buzz on 24hr Media

Blog Article

More About 24hr Media

Table of ContentsThe 8-Minute Rule for 24hr MediaThe 7-Second Trick For 24hr MediaUnknown Facts About 24hr MediaA Biased View of 24hr MediaThe Basic Principles Of 24hr Media

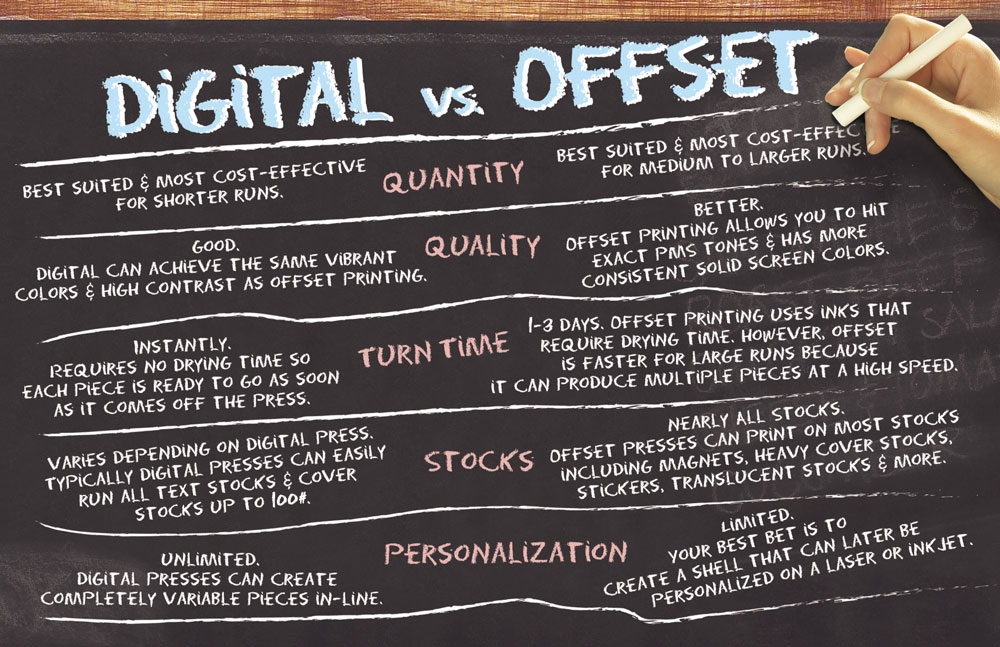

Developments in print modern technology are changing the communications playing field when it involves high quality, price and advanced capabilities. Offset printing and digital printing are the major processes whereby print work are undertaken both using four-color printing techniques. Each choice has its advantages, using different methods to satisfy the requirements of diverse manufacturing tasks.

Typically, this has been one of the most consistent strategy for specifically preserving color suits, making it suitable for print runs that only need static printing such as pre-printed forms, brochures, flyers, calling card, and bulk postcard mailings. Due to the static nature of litho printing, it is not ideal for variable print items that will be mailed to specific receivers such as statements, letters, and individualized postcards.

Getting My 24hr Media To Work

The most recent developments in print modern technology are helping to bring numerous of offset's advantages into the digital printing globe absolutely changing the face of contemporary printing! There are some essential differences between Offset Printing and Digital Printing (Point of sale stands). This guide reveals the benefits and disadvantages of each printing technique. There is an indisputable and expanding variety of benefits to making use of the digital print process.

Today's digital print devices is among the most cutting-edge on the marketplace. Below are a few of the largest benefits of using electronic printing: dominate the digital print space, with full-color printing completed in one process and perfectly printed directly from a print file. Without a lengthy set up process, the calibration time of a details task is reduced, adding to quicker print time and total delivery.

The inkjet printing procedure has aided to reinvent the sector along with the high quality and rate of the result. The most recent inkjet technology can publish on traditional balanced out supplies with boring, silk, and glossy surfaces. High-quality electronic print combined with software-managed shade monitoring techniques adds optimum value to publish pieces and makes manufacturing procedures more reputable than balanced out.

Top Guidelines Of 24hr Media

(http://www.askmap.net/location/7255850/south-africa/24%CA%B0%CA%B3media)

Specific quantities of ink and printer toner are utilized to avoid waste. Environmentally friendly and eco-friendly inks and printer toners are additionally readily available for more sustainable printing. Digital print additionally gets rid of the demand to clean plates or blankets with unsafe chemicals at the end of the printing procedure. As the high quality of electronic print services increases, the advantages come to be significantly obvious and useful.

Variable data assists services reach their exact consumers and target market with uniquely-created and individualized material. As modern technology boosts, the quality of digital printing has actually ended up being second-to-none, with greater detail, color match abilities and general accuracy. Without the look at this site need to clean plates or use excess ink, digital printing is also less wasteful and generally extra environmentally pleasant.

Standard printing techniques, such as offset lithography ("balanced out") and flexography ("flexo"), include several make-ready actions to move an original picture to a substrate. These techniques require the manufacturing of a series of plates installed on a cyndrical tube to transfer ink that creates the desired picture when incorporated on paperboard and other product packaging materials. Digital Printing.

The Best Guide To 24hr Media

While electronic printing is a viable option for many short-run print workspecial occasions, prototyping, or other considerationsits modern-day abilities actually display in rapid turnarounds. Having the ability to personalize product packaging with variable data printing has opened up brand-new chances for you to engage with your consumers in even more individualized ways. Digital printing, with less moving items, is a lot more agile than balanced out hereof.

It's a means to mix your product packaging and marketing methods. Lowered set-up time saves cash on the front end. And since these are not enormous mass orders, smaller services can pay for to publish without needing to fulfill the greater and extra expensive print limits of conventional printing. Digital printing aids protect your brand against counterfeiting by integrating overt and covert solutions on your packaging.

Make sure you collaborate with a printing and packaging partner that has the best accreditations. While eleventh-hour printing and personalization are a big benefit, digital may not constantly be the best approach for you. For instance, offset printing has the advantage of cost-effectiveness with large print runs, particularly those with sophisticated attractive impacts and specialized finishes.

Some Known Incorrect Statements About 24hr Media

The favorable plate, with its smooth surface area, draws in oil-based inks and wards off water. In comparison, the unfavorable plate, with its harsh texture, soaks up water and repels oil. Rubber rollers are then made use of to transfer the picture from the plate to the corrugated surface area.

Corrugated paper can sometimes confirm to be a difficult surface to print on, yet Litho prints to a different surface and is after that laminated flooring to it, making it very easy to print high-grade photos. It can be very regular, also for lengthy runs. As a matter of fact, the a lot more you publish, the more affordable the prices come to be for Litho.

What Litho doesn't offer you is specifically what Digital does, modification. Costly set up Longer turnaround No Variable Data Printing Smaller shade range, shades can be much less brilliant Digital printing is the process of printing digital images directly onto the corrugated substratum making use of a single-pass, direct-to-corrugate strategy.

Report this page